TINOS is a system that can ensure the records and access to work procedures related to any management of technical assets in the company. It can be used in the office and in the field.

Taking care of a large number of different devices so as to ensure their trouble-free functioning is always better with precise records. Therefore, operations technicians create their personal notes and procedures verified by practice. The notes are easy to navigate and the technicians have them at hand. Over the years of experience, they will create a sophisticated system for recording parameters, settings, repair history, and some of them can plan even simple maintenance. It's practical and to some extent it works somehow. After exceeding this limited scope, they switch to specialized software that manages greater scope, substitutability, collaboration, data sharing, reporting, reliability and thus ensures greater labor productivity for the entire company - an information system parameterized for technicians, engineers, foremen and other operations staff. Yes, we have such a system and are constantly improving it, with our customers, for years. From the best practices of large and small companies, we have made cubes that fit together like in a kit. And because our customers also reach the preferred goal through various methods, we will help you choose the path. Choose from the experience of the best in the field and do not repeat their mistakes.

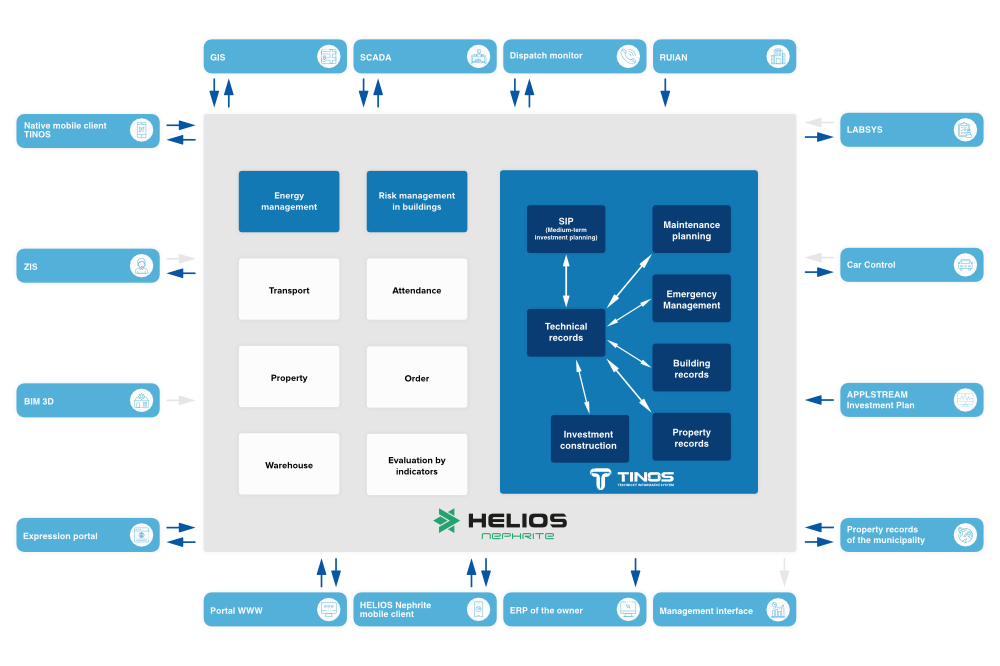

We have a system that tries to make managing technical equipment as easy as possible. Gradually, as other customers came to us, they brought their own records and procedures, which, in addition to our functionalities, they also needed to think out. We have thus programmed into the system the highly advanced professional know-how of employees and experts focused on the same issues, similar work or functional processes and roles. Sometimes they've come a long way, including dead ends and setbacks, before they say, "It's going well now!" And as the years go by and clients come, it's hard to surprise us with something new we don't have yet. That doesn't mean we're not still working. We are constantly improving the original records and procedures and creating new functionalities. We didn't start from scratch either. We are building the TINOS on the HELIOS Nephrite platform. So we don't have to worry about the so-called "system core", i.e. the basic parameters of operation, which in addition to ergonomy of control, status and functioning of forms, summaries, reports and prints provided by an authorized manufacturer for the system used by hundreds of companies and thousands of users. In this way, we can focus exclusively on specialized and precisely defined processes and activities, which we solve with the support of our TINOS.

Thanks to our decision not to start from scratch, but to use the core and strong background of IS HELIOS Nephrite, we have support in customer-proven economic agendas and processes. Records of employees, orders, centers, economic data in invoices or contracts, material movements in a warehouse for completing the order, etc. They directly "grow through" the records of the TINOS. So you can choose directly from employees - who will go where, who is the administrator, from what order, to which center ... There is one system, one common database, one program on the computer, one way of control for everyone, the same administrator, the same database, same interface, same HW. Thanks to a large portfolio of our customers, we already have a connection to a number of proven and specialized information systems in utility companies, such as various GIS, SCADA, ZIS, LABSYS, CAR CONTROL, etc. These are factors that clearly speak in favour of rapid implementation.

Together with the development of functionalities in the TINOS, we are also developing a mobile application. In order for a field technician to be willing to take a mobile phone or tablet in his hands and read what to do on the spot and enter what he is doing, it must be beneficial to him. "Sausage finger" control, no trifles and only the information he currently needs on site. The possibility of downloading the registered instructions, settings, technical sheets and previously taken photos or videos is a sure thing, as well as the display in inverse colors, for conditions of reduced visibility and better battery life. The "wait for signal" should not stall the technician longer than a rolled-up screwdriver. We develop forms and reports tailored to the activities in which they will be used. The data in the device is prepared offline long enough before the activity and their synchronization will take place as needed by the technician after work or when connecting the device to the signal, then the data is sent to the Technical Information System. Thanks to the mobile application, technicians can perform activities without turning on the laptop or carrying documents. Thanks to the map data and integration with GIS, it is possible to see where it is, how the layers of networks are stored, or even to force the approval of the work performed on site.

Are you interested in TINOS and are you interested in more information? Contact us and we will be happy to prepare an offer tailored to your needs.

Ensure records and mediate work procedures related to any operations with technical assets.

We start with records. In the paper age, the pinnacle of systematic order was the paper form. For each situation, there was a different elaborate meaning of boxes, codes and colors, but also well-thought-out procedures, who fills in what and where to take it. We have brought this proven tool to today's modern world. We will help you tidy up what to record and implement electronic forms and procedures. If, over time, you find that you want to record, for example, whether the motors also have thermal protection, add the "Thermal protection" property to the "Electric motor" card type. You can connect the "Yes, No, Not Detected" dial, or make your own "Self-Reversible, Mechanically Reversible, Irreversible, Not Detected, Not present" with a pre-filled value of "Not Detected". All motors will now have the information "Thermal protection - Not identified" on the card. And from now on, you can gradually refine the information, for example with a mobile application directly at the engine’s site. You can connect instructions and revision settings to the card, and photos will flow from the mobile application, from the telemetry of the operating hour and from the GIS position on the map.

We continue with maintenance. Technicians at heart always take care of their equipment so that they can work reliably for as long as possible. The manufacturer, legislation or internal guidelines usually prescribe how often and exactly what to check. With the Maintenance Planning module, it is possible to unify service operation plans for equipment of the same type and schedule them as a service inspection in a car repair shop, including a checklist. Make a maintenance prescription for the "Blower Unit" once a year or after 4000 mth (whichever comes first) and have the technicians carry out the following maintenance tasks: "tighten the screws, check the contacts, check the signaling status, check the function manually / automatically, measuring the insulation condition...“ The technician sees in the mobile application when he has to go to the blower unit, and gradually on the spot gradually ticks what he did, or attaches photos and comments.

In the third step of implementation, we focus on the liquidation of accidents. Whether the impulse comes from telemetry, dispatching, or localization from GIS, the situation will be solved by a service squad, who receives the impulse on their PC or a mobile application, including GPS coordinates. At the emergency site, they will either resolve the situation on the spot or set up other working groups. You will receive additional information, including photos and videos created by the service squad. Follow-up procedures may also be related to the accident, and thanks to our solution and its connection with other systems, we are able to inform residents affected by the accident, shut down the site, secure the accident and provide replacement operations and supply from one system. Thanks to the connection of TINOS directly with the mobile application, everyone works with what suits them and always has up-to-date information.

Fill out the contact form and we will get back to you as soon as we can.